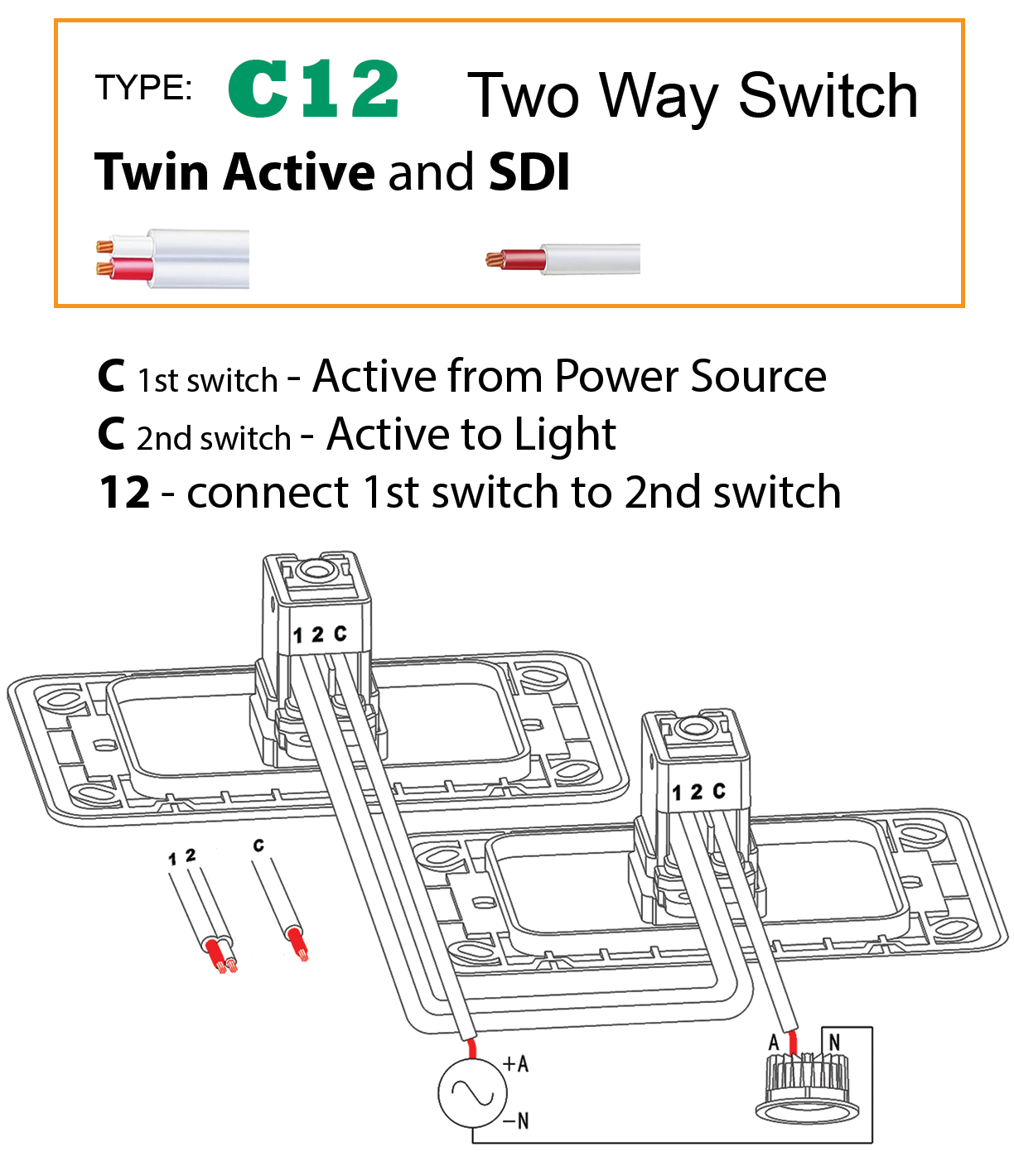

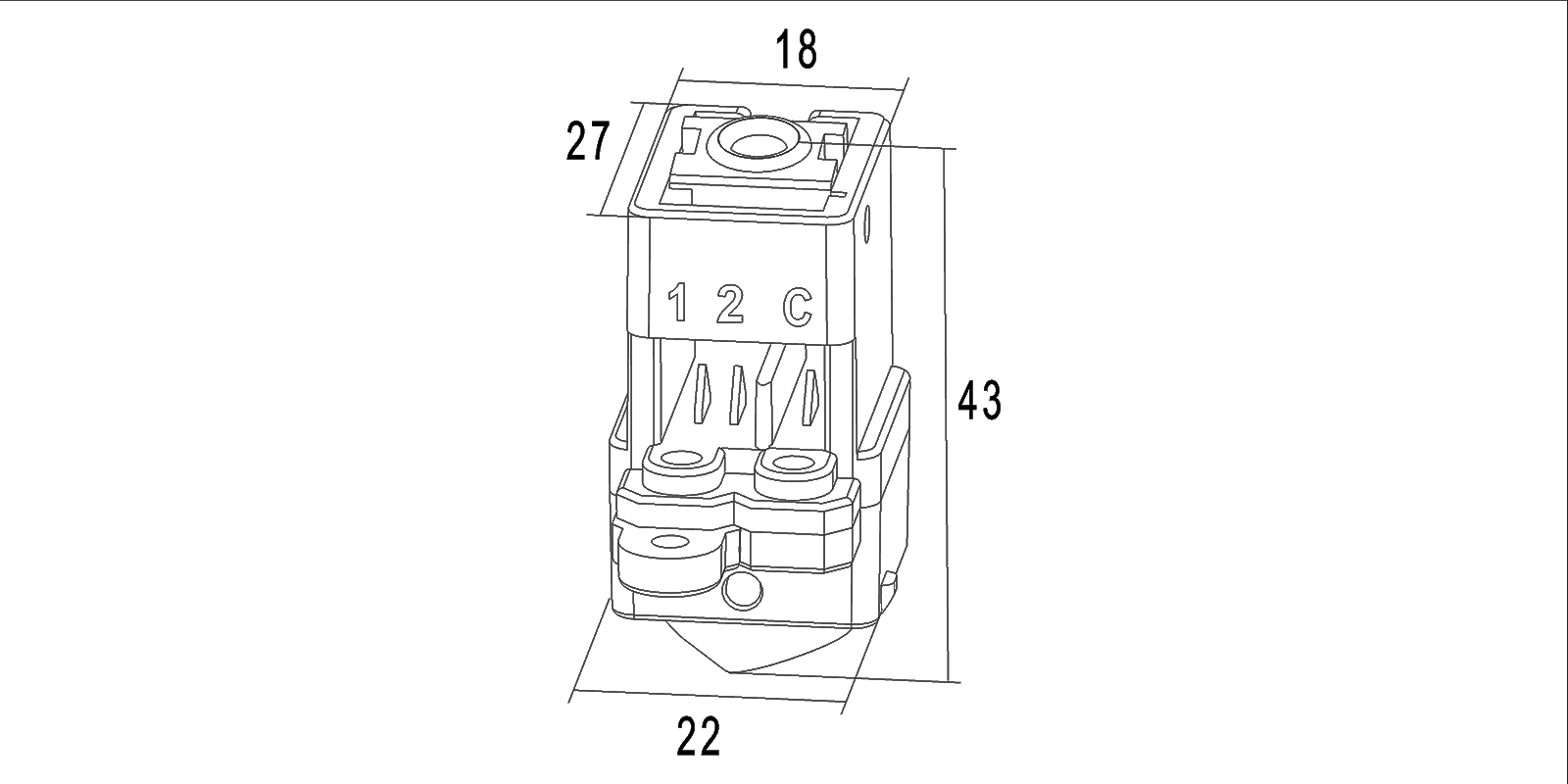

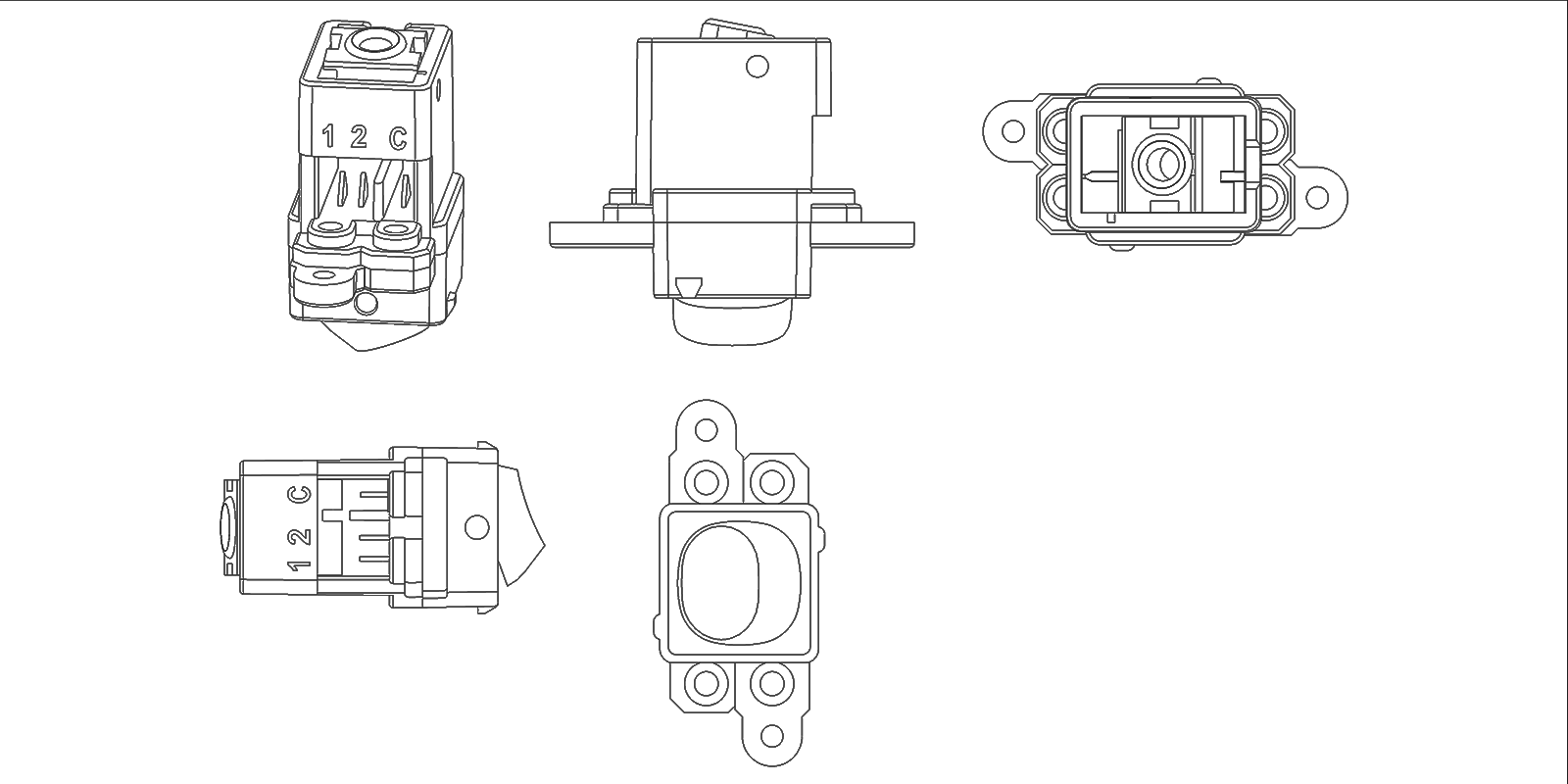

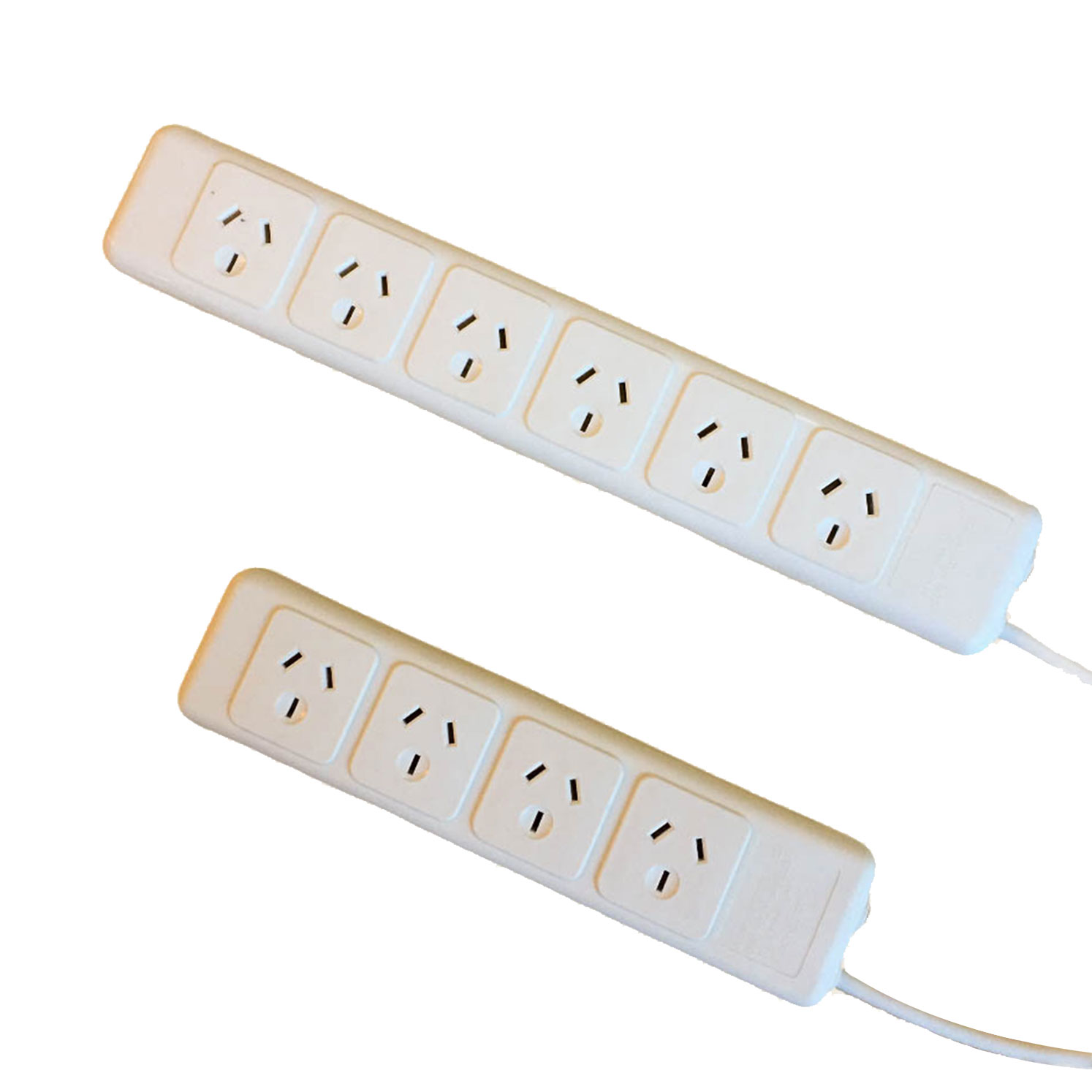

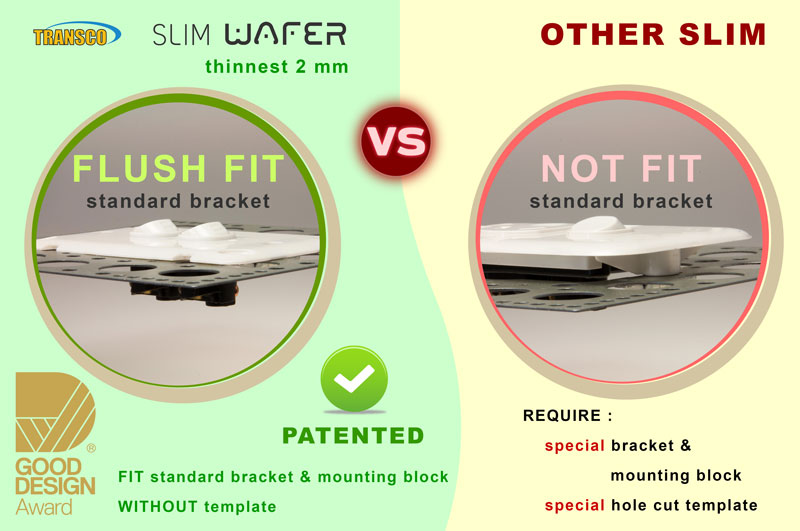

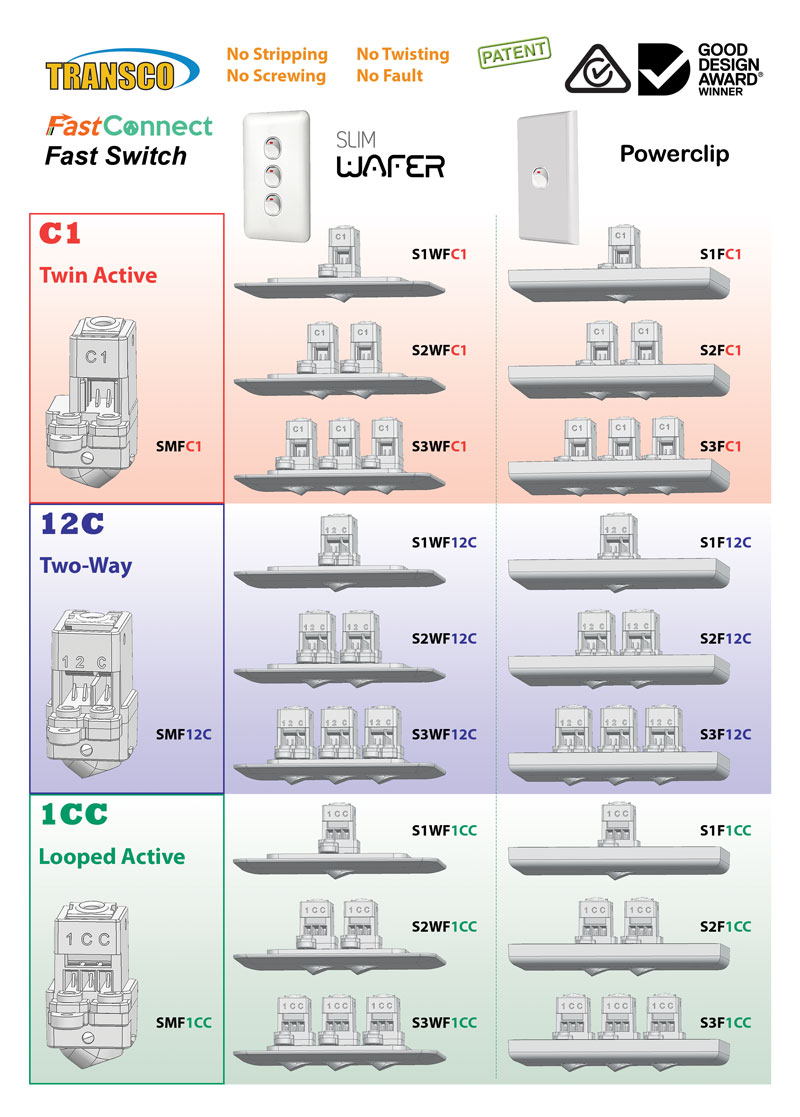

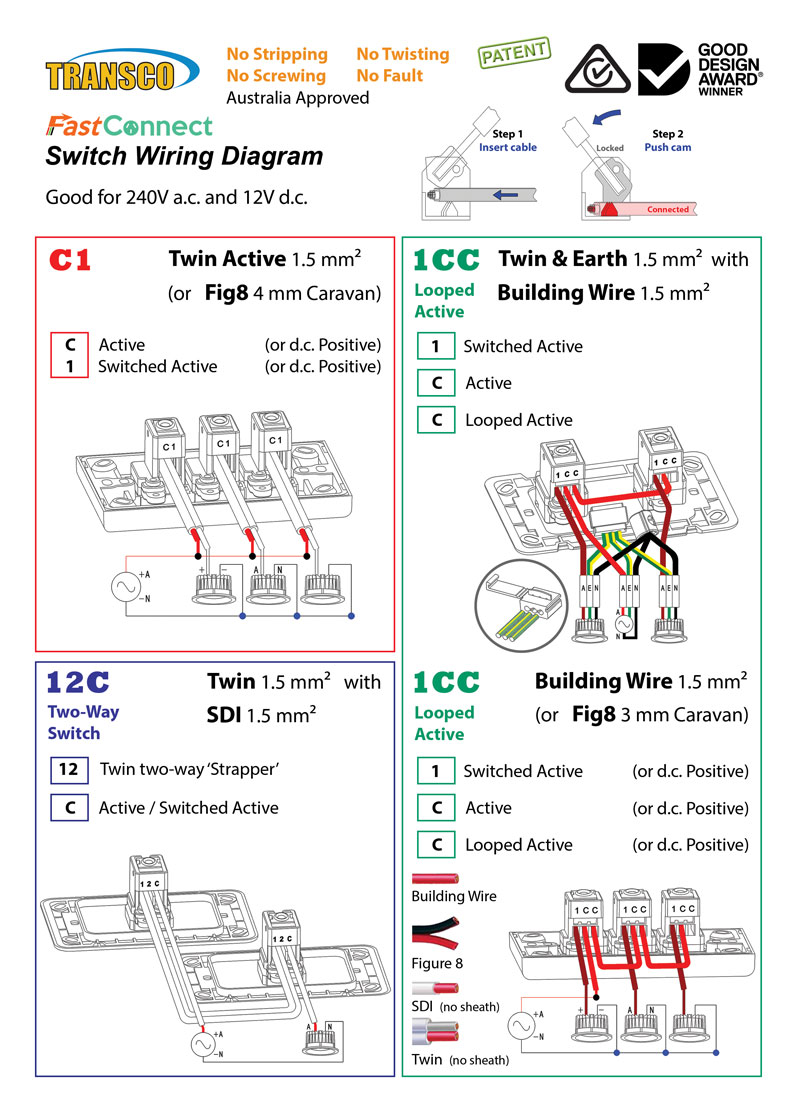

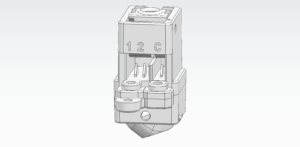

FastConnect Socket Features

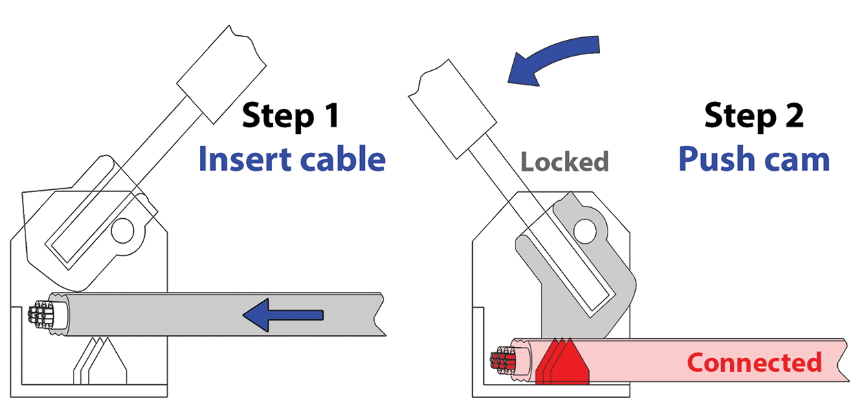

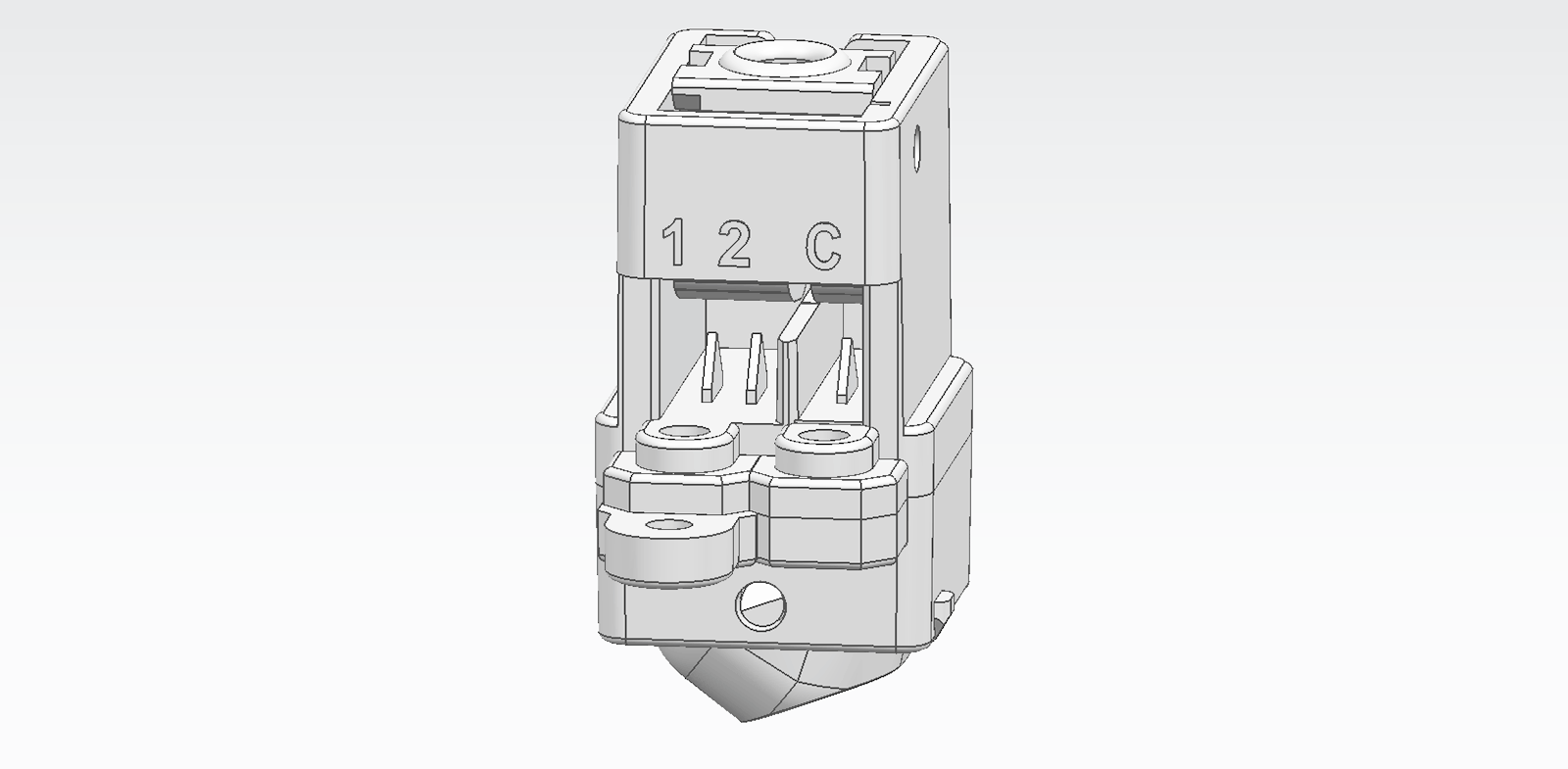

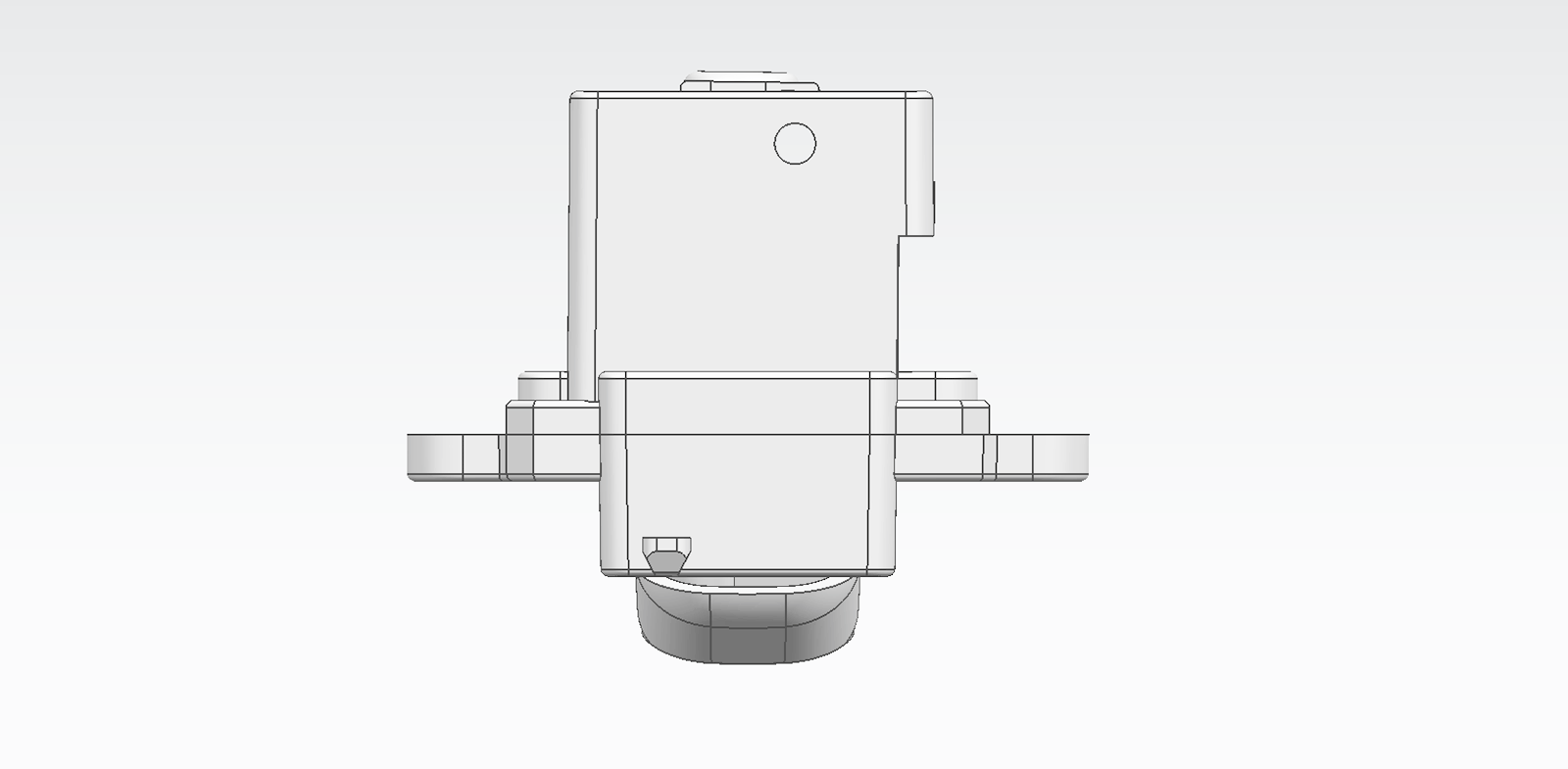

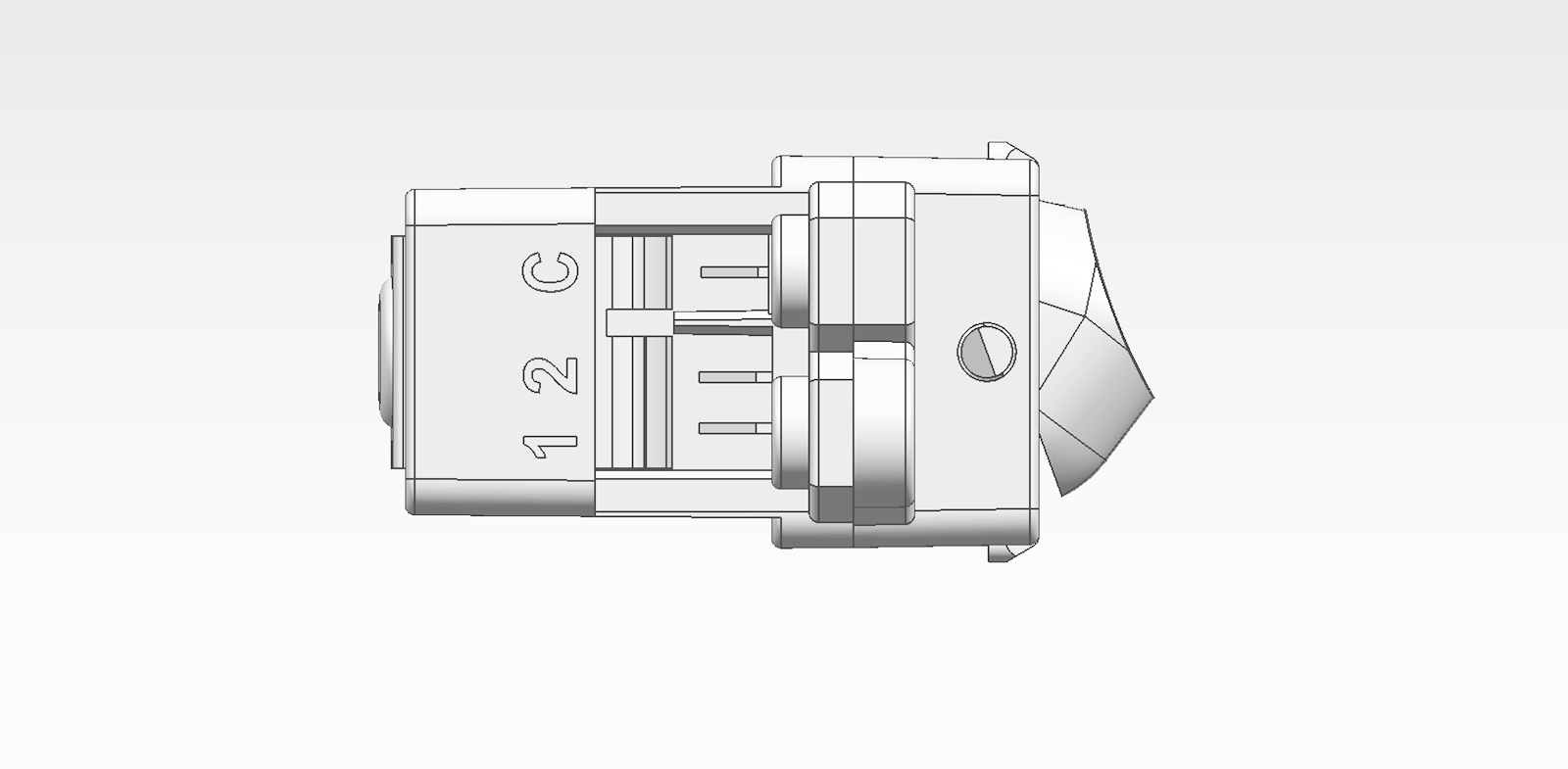

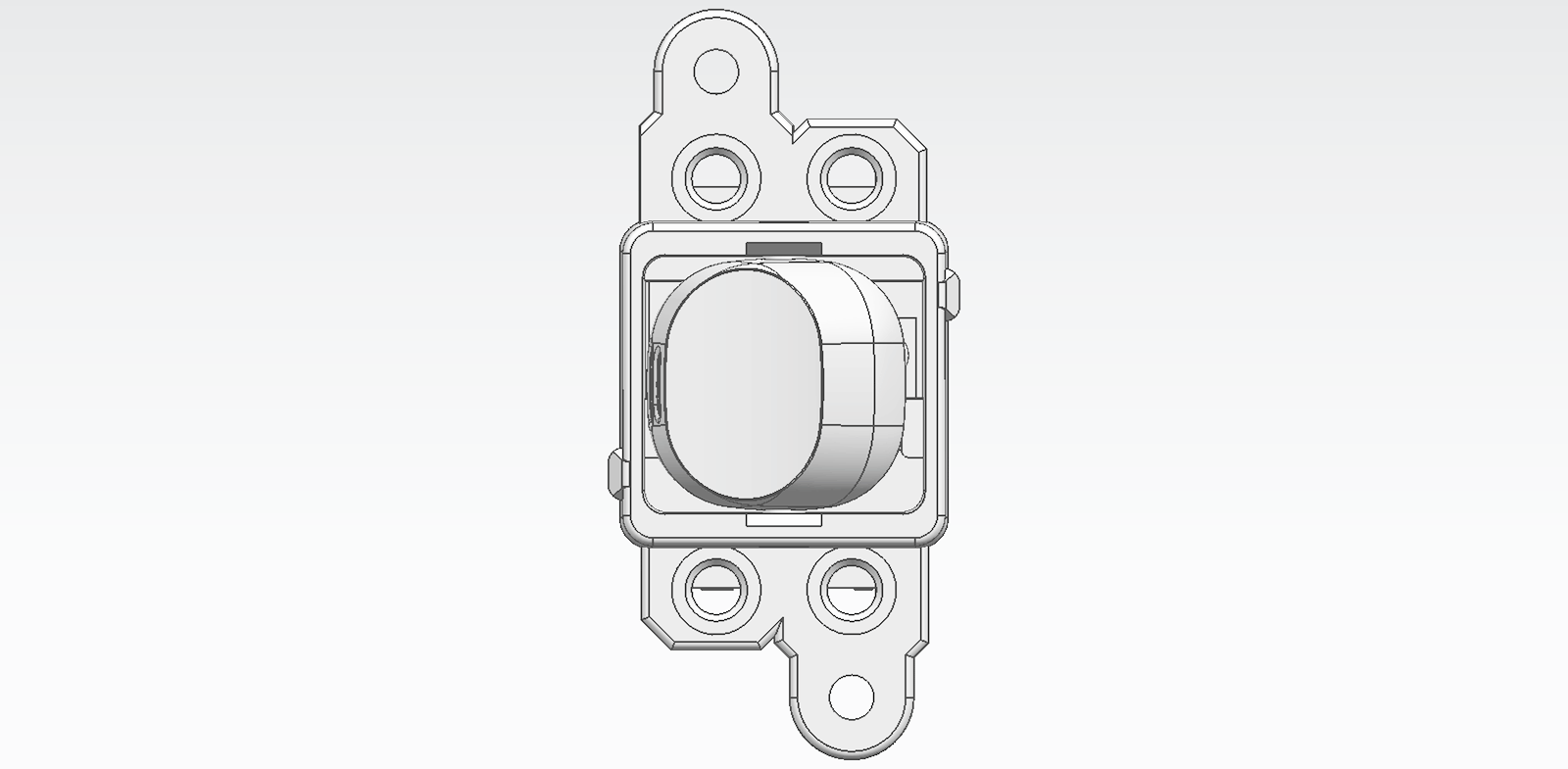

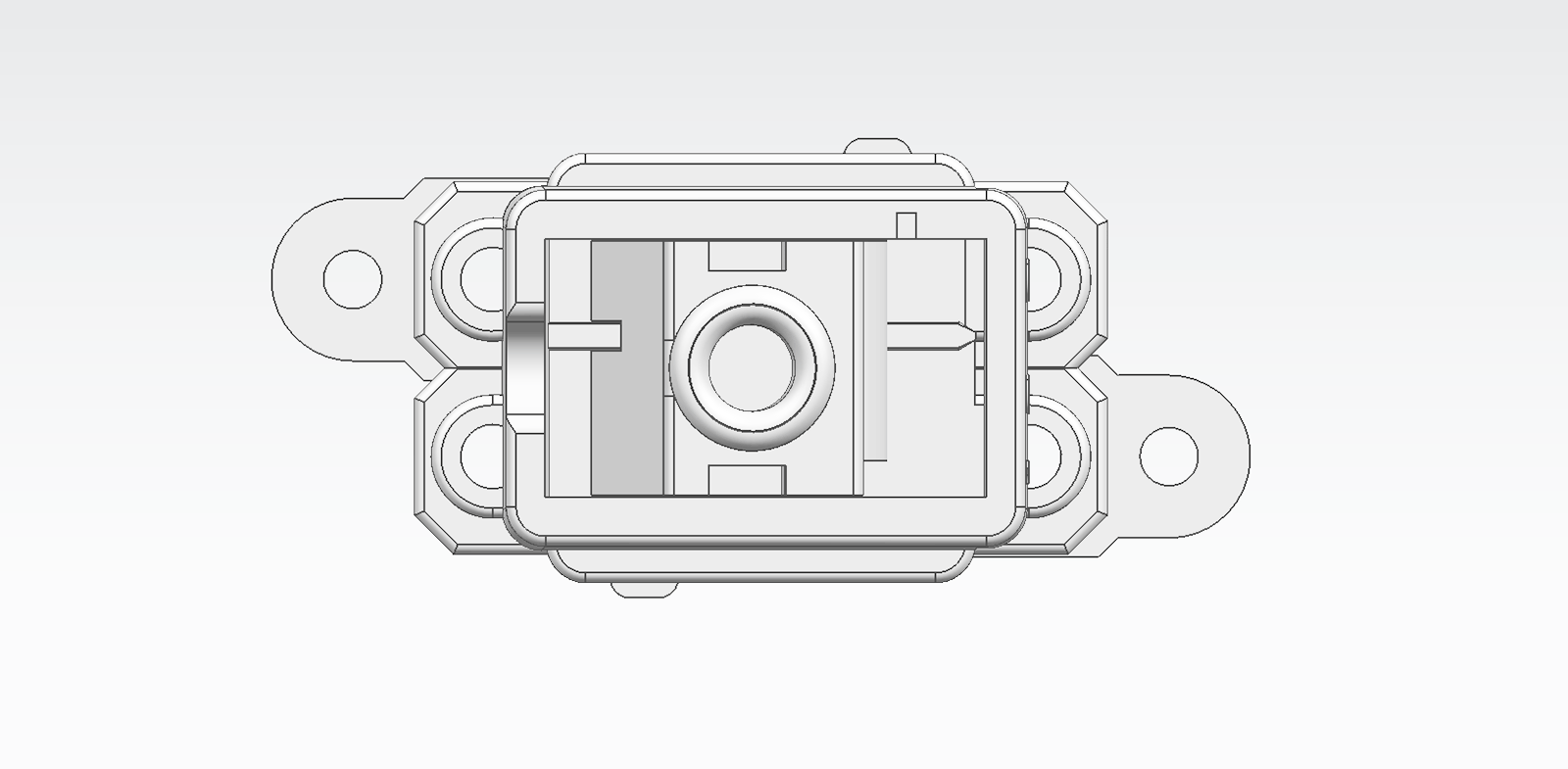

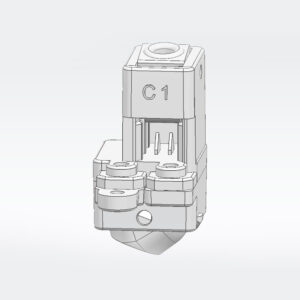

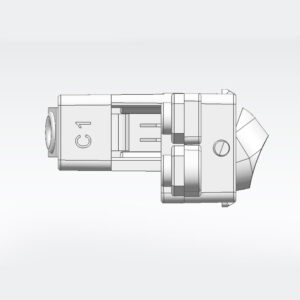

TransFast sockets are a three pin power outlet that allows the user for the first time to connect mid-cable without exposing the cables copper core. Using our patented cam over teeth design you can with speed unparalleled (more than ten times faster than a traditional connection), accuracy (the same high quality connection every time) and enhanced safety (removing the need for user to come in contact with the electrical conductor).The TransFast electrical socket design is the beginning of a connection revolution in the electrical industry.

No need to strip or cut power cable. No need to use pliers, or screwdrivers to make an electrical connection.

A conventional electrical connection is made by using a pair pliers to strip away the layers of insulation, exposing the copper conductors, twisting them together in ad hoc fashion, then screwing them down in a clamping device to make the connection permanent. Our design allows the user to make a high quality electrical connection every time, no matter the users skill level, environment, or time pressure. This is A great leap forward in productivity, and an improvement in safety.

Forward Load Carrying

The copper conductor in electrical cables are stranded (seven cores) and twisted, in a traditional connection it highly possible for a strand or strands to break, reducing the connection area, hence reducing the load capacity. An important feature of our design is the removal of diminished forward load carrying capacity, the Transfast design does not break or breach the cables strands, so loss of forward conductivity through strand breakage is eliminated.

Reduce Cable Waste

Transfast socket outlet reduces the length of “tail” required per connection. Imagine a commercial lighting installation with twenty lights (with led low power consumptions lights this highly possible), the cable is run along the false ceiling with loops (or tails) hanging down where each light is to go. The Transfast design reduces a tail length by 30%, reducing the amount copper and pvc used in each installation. Reductions in off cut and cable stripping waste are made, reducing land fill.